پکیج تصفیه فاضلاب به روش انعقاد الکتریکی

در فرایند انعقاد الکتریکی یا همان Electrocoagulation با استفاده از جریان برق مستقیم (DC) و صفحات فلزی از جنس آلومینیوم و آهن به عنوان الکترود شیمیایی، فاضلاب تصفیه میگردد که به اختصار به این روش EC گفته میشود.

انعقاد الکتریکی یا همان Electrocoagulation یا EC به منظور حذف فلزات سنگین، عوامل TSS و کدورت، COD و BOD، مواد پتروشیمی، رنگ، فلورین، آرسنیک و آلودگیهای آب و خاک در تصفیه فاضلاب و پساب صنایعی همچون نساجی، کشتارگاه، رنگرزی، لبنی، کارواش، نشاسته ، قالیشویی و پتروشیمی به کار می رود.

در روش الکتروکوگولاسیون یا همان انعقاد الکتریکی، الکترودها که شامل آهن و آلومینیوم میباشند؛ مولکولهای هیدروکسید فلزی مانند Al(OH)3 یا Fe(OH)2 را تشکیل میدهند که به دلیل خاصیت جذب بسیار بالا با آلودگیها، تشکیل کمپلکس قابل ته نشین شدن را داده و در نهایت در تانک ته نشینی مربوط به EC از پساب جدا شده و فرآیند تصفیه فاضلاب تکمیل میگردد.

طراحی، ساخت و نصب و راه اندازی انواع پکیجهای تصفیه فاضلاب به روش الکتروکوگولاسیون، انعقاد الکتریکی (Electrocoagulation , EC) با توجه به آنالیز فاضلاب و ماهیت پساب در شرکت فنی مهندسی طرح و کار انجام میگیرد.

شرح فرآیند تصفیه فاضلاب به روش انعقاد الکتریکی، الکتروکوگولاسیون (Electrocoagulation یا EC)

در تصفیه فاضلاب و پسابهای صنعتی؛ وجود انواع رنگ، دترجنت، عوامل بالای کدورت و TSS و همچنین فلزات سنگین، موجب ایجاد مشکل در فرآیندهای تصفیه فاضلاب به روشهای بیولوژیکی (واحدهای هوازی و بی هوازی) میگردند. بنابراین مهندسین و طراحان واحدهای تصفیه فاضلاب میکوشند تا پیش از ورود پساب به واحدهای هوازی و بی هوازی، غلظت آلایندههای سمی که موجب اختلال در فرآیندهای تصفیه زیستی (بیولوژیکی) میشوند را حذف نمایند.

بدین منظور یکی از روشهایی که در تصفیه فاضلاب صنعتی کاربرد ویژه دارد، انعقاد و لخته سازی ذرات و عوامل آلودگی است. ذرات معلق و آلودگیهای پساب که عمدتاً شامل مواد کلوئیدی هستند، به دلیل بار الکتریکی همدیگر را دفع مینمایند و تنها وقتی میتوانیم آنها را از فاضلاب جدا و تصفیه کنیم که بار آنها خنثی بوده و به یکدیگر چسبیده و سنگین شوند و در حوضهای ته نشینی از پساب جدا گردند.

در تصفیه فاضلاب به روش انعقاد الکتریکی از فلزاتی چون آلومینیوم و آهن استفاده میگردد. این فلزات در حین تماس با آب هیدرولیز شده و تولید یونهایی با بار مثبت کرده و در نتیجه ذرات کلوئیدی با بار منفی را خنثی مینمایند و هسته اصلی فلوک قابل ته نشین شدن را در فرآیند تصفیه فاضلاب شکل میدهند.

این فلوک به صورت کمپلکس آلودگی و هیدروکسید فلزی شکل میگیرد و از آنجایی که هیدروکسید فلزی خاصیت جذب بالایی دارد، پکیج انعقاد الکتریکی (EC) یکی از موفقترین روشهای تصفیه فیزیکی وشیمیایی فاضلاب است.

در پکیج انعقاد الکتریکی، الکتروکوگولاسیون (Electrocoagulation یا EC) از جریان برق مستقیم (DC) به منظور ایجاد یک الکترولیت شیمیایی در فاضلاب استفاده میشود.

این جریان برق مستقیم در طی فرآیند تصفیه فاضلاب به روش انعقاد الکتریکی، سبب ایجاد هیدروکسید آهن و یا آلومینیوم میگردد که به علت خاصیت جذب بالا ذرات باردار موجود در فاضلاب را جذب نموده و تشکیل یک کمپلکس قابل ته نشینی را میدهد.

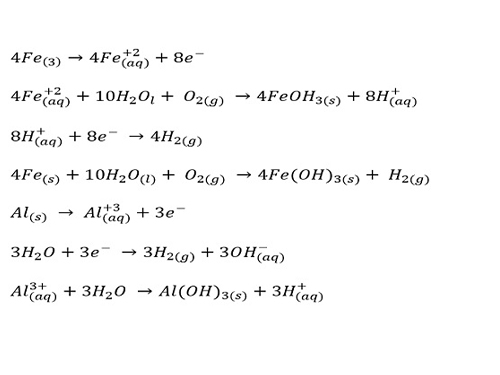

واکنشهای شیمیایی در فرآیند تصفیه فاضلاب به روش انعقاد الکتریکی، الکتروکوگولاسیون (Electrocoagulation یا EC)

در تصفیه فاضلاب به روش انعقاد الکتریکی چند واکنش شیمیایی به صورت همزمان بر روی صفحات کاتد و آند اتفاق می افتد. این واکنشها نتیجه انتقال الکترون از روی صفحات EC در طی فرآیند تصفیه فاضلاب است.

برخی از واکنشهای عمده که در فرآیند تصفیه فاضلاب روی میدهد؛ شامل موارد ذیل است:

همانطور که ملاحظه میشود؛ در تصفیه فاضلاب به روش انعقاد الکتریکی، دو واکنش مجزا روی میدهد.

از یک سو کمپلکس فلزی سنگینی بر پایه هیدروکسید آلومینیوم شکل میگیرد که هسته اولیه فلوک را تشکیل داده و در طی فرآیند تصفیه فاضلاب به روش انعقاد الکتریکی، به صورت لجن ته نشین میگردد.

از سوی دیگر مقادیری گاز در طی فرآیند تصفیه فاضلاب به روش انعقاد الکتریکی آزاد میگردد که سبب شناور سازی ذرات سبکتر بر روی سطح پکیج انعقاد الکتریکی میشود.

عوامل موثر در تصفیه فاضلاب به روش انعقاد الکتریکی، الکتروکوگولاسیون (Electrocoagulation یا EC)

مهمترین عوامل در طراحی و ساخت یک پکیج تصفیه فاضلاب به روش انعقاد الکتریکی یا همان EC؛ پارمترهایی همچون TSS و COD و Oil & Grease و دترجنت و فلزات سنگین، دما و pH است.

بر این اساس میزان جریان و ولتاژ مورد نیاز، تعداد و نوع الکترودها و حجم راکتور اصلی و تانک ته نشینی مورد نیاز جهت تصفیه فاضلاب به روش انعقاد الکتریکی (EC) محاسبه میگردد.

ساخت و مونتاژ پکیج انعقاد الکتریکی (الکتروکوگولاسیون) یا همان Electrocoagulation یا EC پس از تهیه و تنظیم نقشههای ساخت و بر اساس استانداردهای رایج در کارگاه شرکت فنی مهندسی طرح و کار (دپارتمان تصفیه فاضلاب) انجام میپذیرد.

کاربرد پکیج انعقاد الکتریکی، الکتروکوگولاسیون (Electrocoagulation یا EC) در صنایع تصفیه فاضلاب

استفاده از انعقاد الکتریکی به دلیل قابلیت بالا در حذف آلودگیهای زیر در تصفیه فاضلاب کارایی دارد:

عوامل مربوط به TSS و کدورت

روغن و گریس (Oil & Grease)

کف و دترجنت

فلزات سنگین

رنگ

فلورین، آرسنیک

آلودگی های آب و خاک

بر این اساس از پکیج انعقاد الکتریکی یا همان Electrocoagulation یا EC میتوان در تصفیه فاضلاب بسیاری از صنایع استفاده نمود که برخی از آنها شامل موارد ذیل میباشند:

۱- فاضلاب پتروشیمی و فرآورده های نفتی

در تصفیه فاضلاب پتروشیمی و فرآورده های نفتی به منظور حذف روغنهای سنگین، پارافین و برخی ترکیبات آلی و هیدروکربنها با شاخههای طولانی کربن.

۲- فاضلاب لاستیک سازی

در تصفیه فاضلاب لاستیک سازی به منظور حذف پلمیرها و شاخههای کربنی طولانی.

۳- فاضلاب صنایع لبنی

در تصفیه فاضلاب صنایع لبنی به منظور حذف چربی محلول و کاهش TSS

۴- تصفیه فاضلاب نساجی

در تصفیه فاضلاب نساجی و رنگرزی به منظور حذف رنگ و اسیدهای چرب غیر محلول

۵- تصفیه فاضلاب نشاسته و گلوکز

در تصفیه فاضلاب نشاسته و گلوکز به منظور کاهش چربی و از بین بردن کربوهیدراتهای نامحلول

۶- فاضلاب کارواش

در تصفیه فاضلاب کارواش به منظور از بین بردن کف و دترجنت و کاهش TSS پساب و ATPE ها

۷- تصفیه فاضلاب کشتارگاهها

در تصفیه فاضلاب مراکز کشتارگاه به منظور حذف و کاهش TSS، چربیهای موجود در فاضلاب

۸- تصفیه فاضلاب صنایع آبکاری فلزات

در تصفیه فاضلاب صنایع آبکاری فلزات به منظور حذف فلزات سنگین از قبیل کرم

نتایج استفاده از پکیج الکتروکوگولاسیون (Electrocoagulation یا EC) در تصفیه فاضلاب

در پکیج انعقاد الکتریکی (Electrocoagulation یا EC) فلزات سنگین با راندمان ۹۹٪ حذف خواهند شد. حذف دترجنت، مواد معلق و چربی و نهایتا حذف COD با راندمان بالای ۵۰٪ را خواهیم داشت. همچنین میزان TSS با توجه به ماهیت آن بین ۵۰% الی ۸۰% حذف خواهد شد و تمام این عوامل باعث شده تا روش انعقاد الکتریکی در تصفیه فاضلاب و پسابهای صنعتی به کار گرفته شود.

مزایای استفاده از پکیج الکتروکوگلاسیون (Electrocoagulation یا EC) در سیستمهای تصفیه فاضلاب

استفاده از پکیج انعقاد الکتریکی در صنایع تصفیه فاضلاب؛ نسبت به روش انعقاد شیمیایی به لحاظ اقتصادی مقرون به صرفهتر است و این به دلیل کاربرد جریان برق مستقیم به جای تزریق مواد شیمیایی است.

در روش الکتروکوگولاسیون (Electrocoagulation یا EC) صرفاً صفحات (الکترودهای) آهن یا آلومینیوم به تدریج مصرف شده و پس از چند سال نیاز به تعویض دارند. درحالی که در روش انعقاد شیمیایی، همه روزه مقادیر بالایی از مواد افزودنی به منظور تنظیم pH ، مواد منعقد کننده و کمک منعقد کننده پلیمری بایستی به پساب تزریق گردد که هزینههای بهره برداری سیستم تصفیه فاضلاب را به شدت افزایش میدهد.

به طور کلی مزایای تصفیه فاضلاب به روش انعقاد الکتریکی شامل موارد زیر است:

میزان کمتر یونهای انعقادی مورد نظر

راندمان حذف آلاینده بالاتر

عدم نیاز در مصرف مواد شیمیایی

لجن تولیدی کمتر

زمان واکنش کم

نیاز به رآکتور تصفیه فاضلاب با حجم کمتر

مقرون به صرفه بودن هزینههای اقتصادی

پروژه اجرایی تصفیه فاضلاب، پکیج انعقاد الکتریکی، الکتروکوگلاسیون (Electrocoagulation یا EC)

یکی از پروژههای اجرایی شرکت فنی مهندسی طرح و کار که توسط گروه مهندسی تصفیه فاضلاب این شرکت طراحی و به بهره برداری رسید، تصفیه فاضلاب نساجی بود که یکی از فرایندهای آن روش انعقاد الکتریکی یا همان EC است.

مشخصات کلی این پروژه تصفیه فاضلاب به شرح زیر میباشد:

| دبی فاضلاب ورودی | ۳۵ مترمکعب در روز |

|---|---|

| کل اکسیژن خواهی شیمیایی | ۴۰۰۰ میلیگرم در لیتر |

| کل جامدات معلق | ۱۰۰۰ میلیگرم در لیتر |

| روش تصفیه فاضلاب | انعقاد الکتریکی (EC) |

| نوع الکترودها | آهن و آلومینیوم |